TPC is your resource for tube and wire assemblies such as:

Transmission control lines

![]() Vacuum brake booster line

Vacuum brake booster line

![]() Vacuum supply harnesses

Vacuum supply harnesses

![]() Windshield tubing

Windshield tubing

![]() Head lamp washer system tubing

Head lamp washer system tubing

![]() Oil Transfer & Filter Assemblies

Oil Transfer & Filter Assemblies

![]() Seat frame

Seat frame

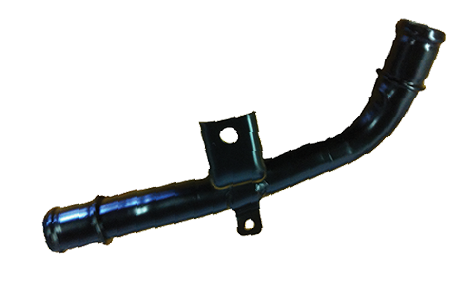

![]() Fuel fill tube

Fuel fill tube

![]() Prowler luggage rack

Prowler luggage rack

![]() Gas furnace burner

Gas furnace burner

![]() Gas mask water tube

Gas mask water tube

![]() Exhaust headers

Exhaust headers

![]() Gear shift lever

Gear shift lever

![]() Seat adjusting lever

Seat adjusting lever

![]() Hood Prop Rod

Hood Prop Rod

![]() Fuel tank filler spuds

Fuel tank filler spuds

![]() Jeep rock slider rail

Jeep rock slider rail

![]() Thermal insulation

Thermal insulation

![]() Heat Sleeves

Heat Sleeves

![]() Thermal Blankets

Thermal Blankets

![]() Industrial Carbon Steel Wire

Industrial Carbon Steel Wire

![]() Alloy Steel Wire

Alloy Steel Wire

![]() Cluster Tubes for brake and fuel lines

Cluster Tubes for brake and fuel lines

![]() Pretensioner tubes

Pretensioner tubes

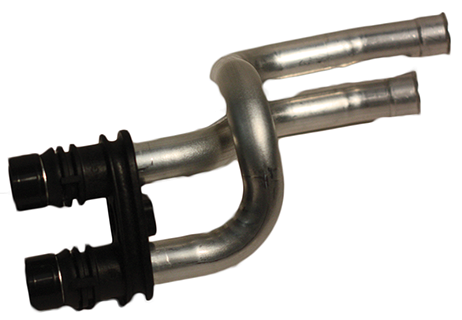

![]() Water tubes

Water tubes

![]() Fuel senders

Fuel senders

![]() Oil cooler tubes

Oil cooler tubes

![]() Energy Absorbing Tube

Energy Absorbing Tube

![]() Heat Protection Tubing

Heat Protection Tubing

![]() Spring Lock Couplings

Spring Lock Couplings

![]() Engineered Tube

Engineered Tube

![]() Fuel rail tubes

Fuel rail tubes

![]() OBVR Fuel Emission Tube

OBVR Fuel Emission Tube

![]() Transfer case oil pump tube assembly

Transfer case oil pump tube assembly

![]() Vacuum brake tube

Vacuum brake tube

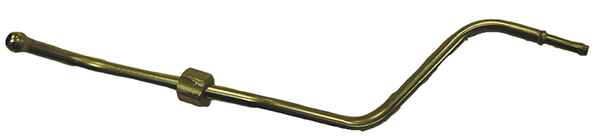

![]() Hydraulic Clutch Actuation Tube

Hydraulic Clutch Actuation Tube

![]() Air leveling lines and assemblies

Air leveling lines and assemblies

![]() Air suspension lines and assemblies

Air suspension lines and assemblies

![]() Central hydraulic tubing

Central hydraulic tubing

![]() Central lubrication tubing

Central lubrication tubing

![]() Chemical tubing

Chemical tubing

![]() Emission control harnesses

Emission control harnesses

![]() Emission line tubing

Emission line tubing

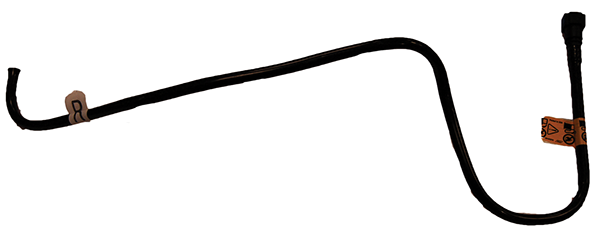

![]() Fuel rail cross-over lines

Fuel rail cross-over lines

![]() HVAC tubing and assemblies

HVAC tubing and assemblies

![]() Hydraulic clutch tubes

Hydraulic clutch tubes

![]() Hydraulic suspension tubing

Hydraulic suspension tubing

![]() Seat umbas air lines

Seat umbas air lines

![]() Mono-layer fuel line tubing

Mono-layer fuel line tubing

![]() Pre-formed fuel line tubing

Pre-formed fuel line tubing

![]() On-board vapor recovery lines

On-board vapor recovery lines

![]() Pneumatic tubing

Pneumatic tubing

![]() Power brake reservoir return lines

Power brake reservoir return lines

![]() Remote reservoir lines

Remote reservoir lines

![]() Nylon monowall tube

Nylon monowall tube

![]() Multilayer nylon tube

Multilayer nylon tube

![]() Welded low carbon steel tube

Welded low carbon steel tube

![]() Aluminum tube

Aluminum tube

![]() Stainless steel tube

Stainless steel tube

![]() Low carbon steel wire

Low carbon steel wire

![]() Overmolded

Overmolded

Processes

Tube fabrication

Screw machines

Stainless steel tube manufacturing

Thermoplastic tube extrusions

Complex thermoformed bending

Press Forming

Punching/Notching

Stamping

Hydroforming

Tube end forming

Custom, Multi-axis bending

Design support and development services

Assembly & Testing

Shaving

Annealing

Centerless Grinding

Materials

Metal/Steel

Low carbon

Low carbon

High-Strength-Low-Alloy (HSLA)

High-Strength-Low-Alloy (HSLA)

Stainless Steel (most grades)

Stainless Steel (most grades)

Copper

Copper

Brass

Brass

Aluminum

Aluminum

Titanium

Titanium

Incoloy

Incoloy

Industrial Carbon Steel Wire

Industrial Carbon Steel Wire

Alloy Steel Wire

Alloy Steel Wire

PA/PC-Coated tubing

PA/PC-Coated tubingPlastic

Nylon (Polyamide) 6, 66, 612, 11 & 12

Nylon (Polyamide) 6, 66, 612, 11 & 12

Polyethylene (LDPE, LLDPE, HDPE)

Polyethylene (LDPE, LLDPE, HDPE)

TPE / TPU Thermoplastic elastomers

TPE / TPU Thermoplastic elastomers

Mono or multi-layer tubing

Mono or multi-layer tubing

Plastic convoluted tubing

Plastic convoluted tubingDimensional Limits

Dimensional Limits

Product tube size ranges from 0.75mm [0.030”] to 175mm [7.000”] diameter and above for some operations.

Tube wall thickness may range from 0.15mm [0.006”] to 12.0mm [0.500”]

Wire diameters up to 9.0mm [0.375”] may be fabricated.

Beading 2.5" diameter low carbon steel tube with .083" wall

3" tube diameter capacity

Plastic Tubing: Cut to length and coil tubing up to 30 mm in diameter

Wire Fabrication:

Diameter: 0.70” to .950”

Standard Bar Size Range

Cold Drawn Bars: 0.090" - 0.785"

Centerless Ground Bars: 0.090"- 0.760"

Finishes

Plated

Plated

Powder coated

Powder coated

Anodizing

Anodizing

E-coating

E-coating

Powder painting

Powder painting

Wet spray

Wet spray

Buffing/polishing

Buffing/polishing

Heat treating

Heat treating

Wire:

Wire:Zinc Phosphate & Lime

Zinc Phosphate & Polymer

Zinc Phosphate & Liube

Zinc Phosphate Lime & Grease Drawn

Lime & Grease Drawn

Lime & Stearate

Copper Coating

Wire Tolerances

Wire Tolerances:

+/-0.0005”

Standard wire size tolerance:

0.070" - 0.130" +/- 0.0005"

0.131" - 0.400" +/- 0.0010"

0.401" - 1.010" +/- 0.0015"

ABOUT OUR TEAM

Our team members have decades of experience in the automotive industry and related fields, a wealth of product knowledge and will provide excellent service. We offer competitive pricing, high quality products and creative solutions to the challenges you face. We look forward to meeting and working with you.

PRODUCTS

CONTACT US

2545 North Opdyke Road, Suite 101

Auburn Hills, MI 48326 USA

TEL 248.370.9600

EMAIL info@tpcsales.com

Office hours Monday - Friday, 8:30 to 5:00 EST

©2015 Tubular Products Company. All rights reserved.